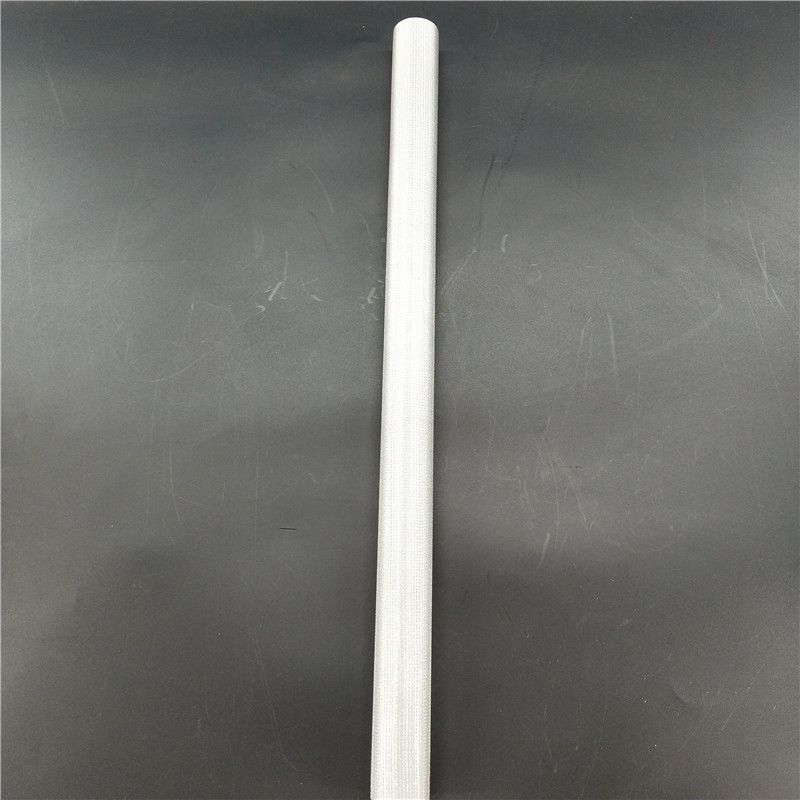

Introduction to sintered mesh filter element:

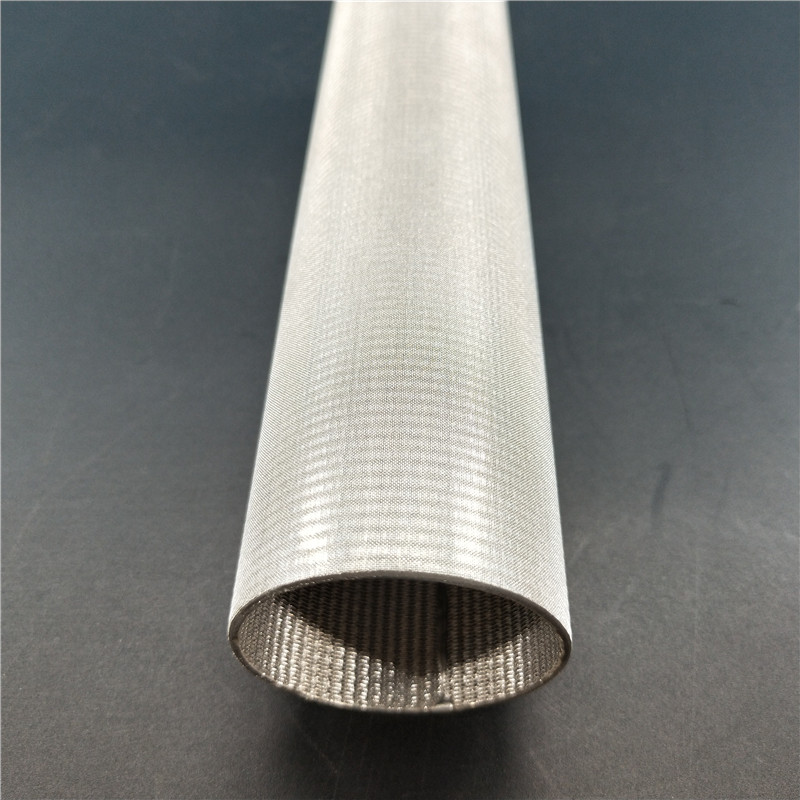

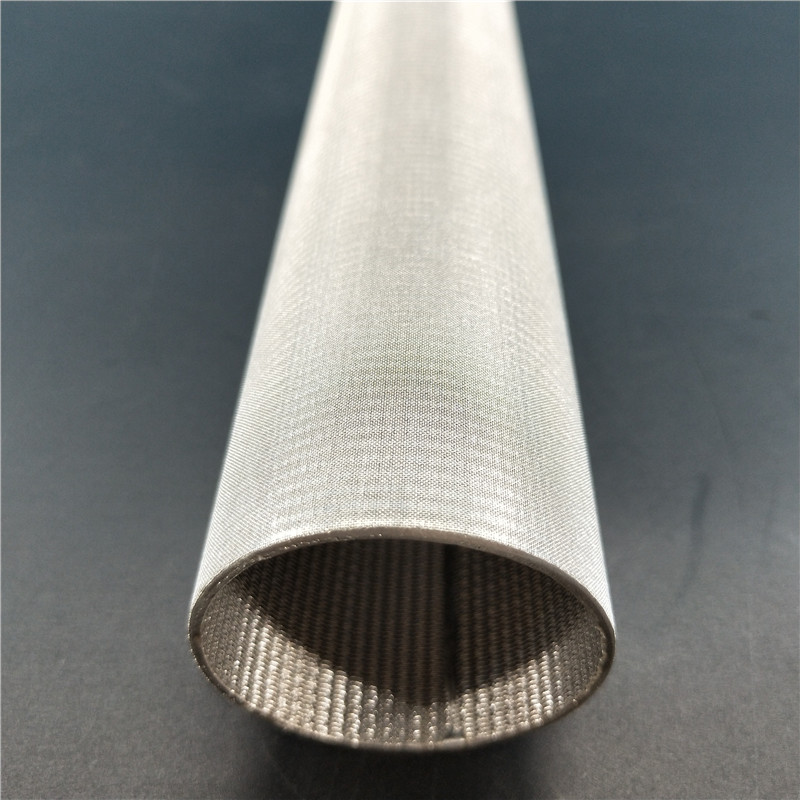

The mesh of each layer of mesh is staggered to form a uniform and ideal filter structure, which not only overcomes the shortcomings of low strength, poor rigidity and unstable mesh shape of ordinary metal mesh, but also can control the pore size The permeability and strength characteristics are reasonably matched and designed, so that it has excellent filtration accuracy, filtration impedance, mechanical strength and processability. The comprehensive performance is higher than that of ordinary metal filter element.

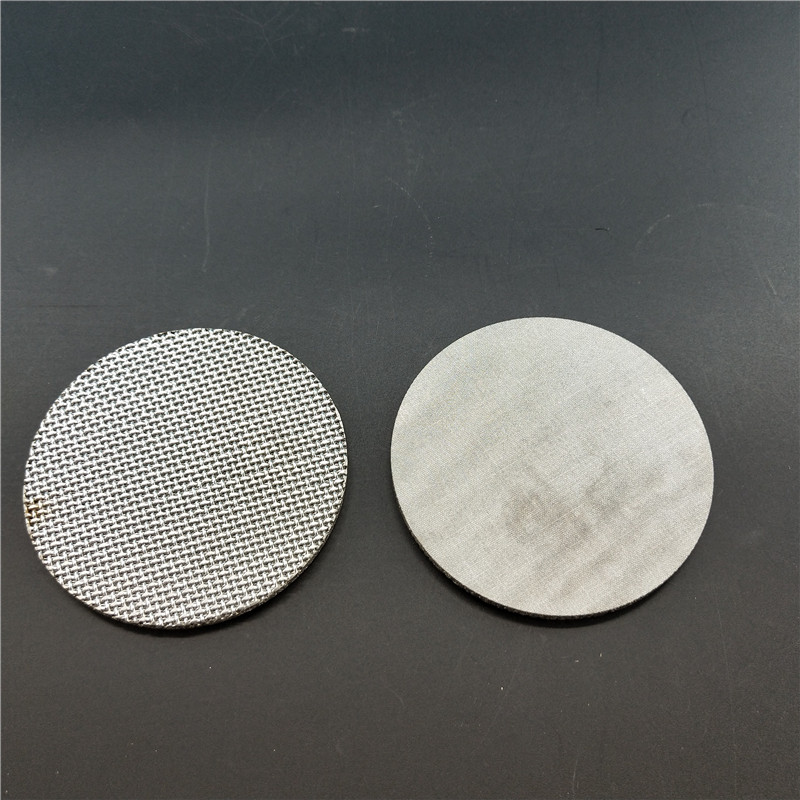

Filter Media: sintered mesh

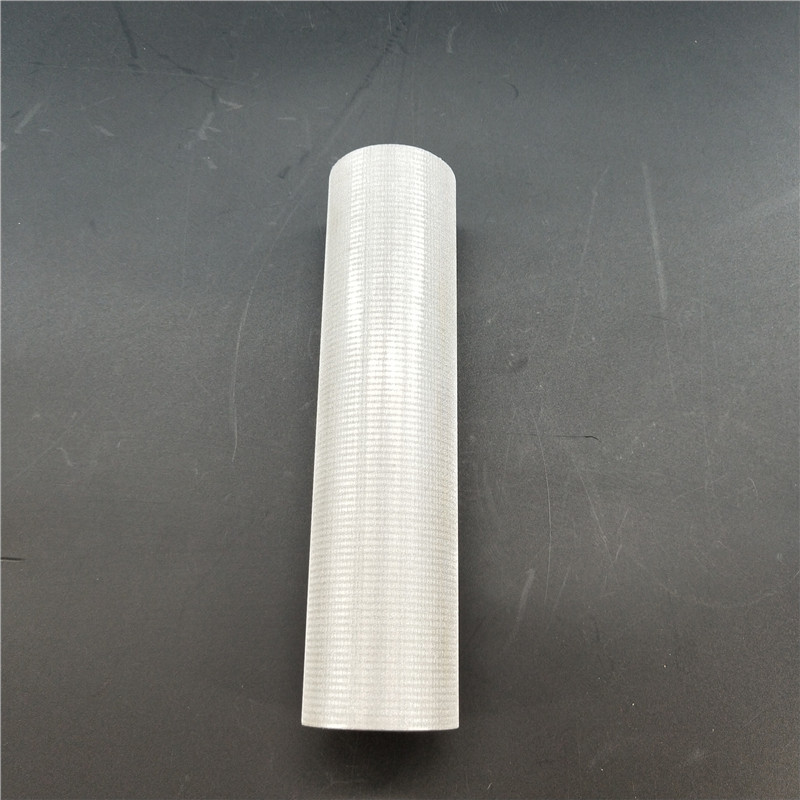

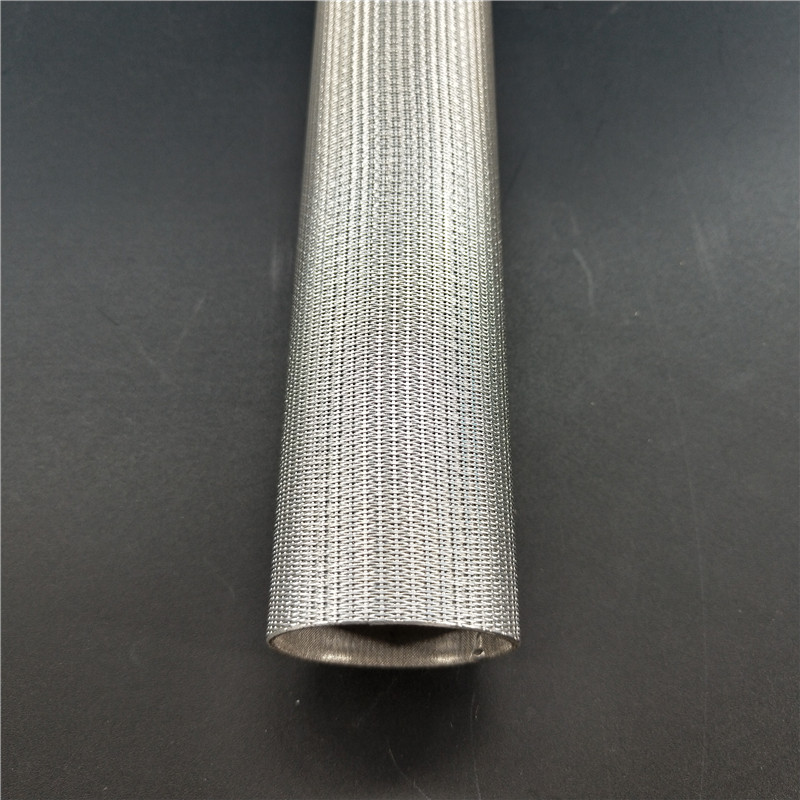

Sintered mesh filter is made of sintered mesh after cutting, precision welded sintered filter. The most important point of Sintered felt filter element is that a large number of high-precision welding is used. To ensure roundness and flat, Sintered wire mesh filter cartridge is sintered after using rolling seam welding process and the method of correction weld, it can make the overall look more beautiful.

Main filter medium of sintered filter elements is five-layer sintered wire cloth, filter rating is form 1 to 200 micron. Five-layer sintered wire cloth consists of five layers of stainless steel mesh, which are sintered together in vacuum.

Features of sintered mesh filter element

1. High strength and good rigidity: it has high mechanical strength, good processing, welding and assembly performance and easy to use.

2. Uniform and stable accuracy: uniform and consistent filtering performance can be achieved for all filtering accuracy, and the mesh does not change during use.

3. Service environment: it can be used for filtration in - 20 ℃ ~ 600 ℃ temperature environment and acid-base environment.

4. Excellent cleaning performance: good counter current cleaning effect, reusable and long service life (counter current water, filtrate, ultrasonic, melting, baking and other methods can be used for cleaning).

Alloy

Stainless Steel, Duplex SS, Supper Duplex SS, Monel, Hastelloy, Inconel, FeCr Al, Fe3Al etc.

Advantage

-Uniform hole, accurate filtration rate

-High hardness and good abrasion resistance

-Excellent resistance to erosion, heat and pressure

Specification

-Filtration rate: 1-200μm

-Temperature: -50℃-800℃

-Diameter:14-800mm, Length:10-1200mm

-Hanke Filter can be customized by your demands.

Application

-Polyester

-Petrochemical, petroleum refining

-Pharmaceutical and food refining or cycling

-Drinking

-Catalytic recycling